The future of plastic raw material production and innovation is being shaped by a combination of sustainability goals, regulatory pressures, technological advancements, and shifting consumer preferences. These trends are driving the development of new materials, processes, and business models to meet the demands of a rapidly changing global market. Here are the key trends:

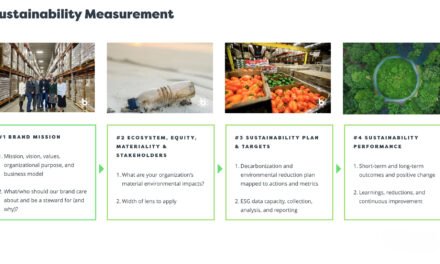

1. Sustainability and Circular Economy

- Recycled Plastics:

- Increasing adoption of recycled plastics, including advanced techniques like chemical recycling, which breaks down plastics into their monomers for reuse.

- Growth in rPET (Recycled PET) and recycled HDPE for packaging and consumer goods.

- Bio-Based Plastics:

- Expansion of plastics derived from renewable feedstocks, such as polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and bio-polyethylene (Bio-PE).

- Use of non-food feedstocks like algae, agricultural waste, and lignocellulose to avoid competition with food production.

- Compostable and Biodegradable Materials:

- Development of compostable plastics that degrade in natural or industrial composting environments, such as PLA and PHA.

- Innovations in marine-degradable plastics to address ocean pollution.

- Carbon-Neutral Production:

- Efforts to reduce carbon footprints by using renewable energy in plastic production and adopting carbon capture technologies.

2. Advanced Recycling Technologies

- Chemical Recycling:

- Techniques such as pyrolysis, depolymerization, and solvolysis that convert plastic waste into raw materials or feedstocks for new plastics.

- Focus on overcoming challenges like energy consumption and scalability.

- Enhanced Mechanical Recycling:

- Improved sorting and cleaning technologies to reduce contamination and maintain the quality of recycled plastics.

- Closed-Loop Systems:

- Development of circular economy models where plastics are continuously reused, reducing dependency on virgin materials.

3. High-Performance Materials

- Engineering Plastics:

- Increasing demand for high-performance materials like polyetheretherketone (PEEK), polyphenylene sulfide (PPS), and liquid crystal polymers (LCPs) in aerospace, automotive, and electronics.

- Lightweight Materials:

- Development of lightweight yet durable plastics for automotive and aerospace industries to improve fuel efficiency and reduce emissions.

- Conductive and Smart Plastics:

- Growth in electrically conductive plastics for use in electronics, sensors, and EMI shielding.

- Smart plastics with self-healing, shape-memory, or responsive properties for advanced applications.

4. Integration of Nanotechnology

- Nanocomposites:

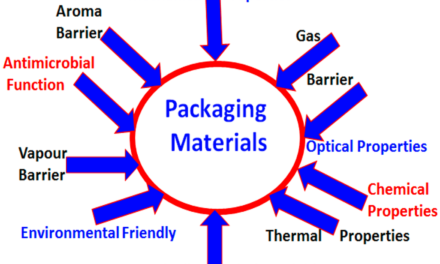

- Incorporation of nanomaterials like graphene, carbon nanotubes, and nanoclays to improve mechanical, thermal, and barrier properties.

- Enhanced Barrier Performance:

- Use of nanotechnology to create plastics with superior resistance to gases, moisture, and chemicals, especially for food and pharmaceutical packaging.

5. Digital Transformation in Manufacturing

- Data-Driven Material Development:

- Use of artificial intelligence (AI) and machine learning to design new polymers and optimize production processes.

- Additive Manufacturing (3D Printing):

- Growth in polymer materials tailored for 3D printing, including bio-based and engineering-grade plastics.

- Blockchain for Traceability:

- Adoption of blockchain technology to enhance traceability in the sourcing and recycling of plastic raw materials.

6. Regulations and Compliance

- Single-Use Plastic Bans:

- Stricter regulations banning single-use plastics are pushing the industry to develop sustainable alternatives and reusable packaging solutions.

- Global Standards for Recycled Content:

- Policies requiring a minimum percentage of recycled content in packaging and products are driving demand for recycled plastics.

- Eco-Labeling:

- Increased emphasis on certifications like ISCC Plus and Ellen MacArthur Foundation standards for sustainable plastics.

7. Consumer-Driven Innovation

- Sustainable Packaging:

- Development of eco-friendly, reusable, and recyclable packaging solutions in response to consumer demand.

- Aesthetic and Functional Features:

- Integration of holographic films, smart labels, and interactive elements in plastic packaging to enhance consumer engagement.

8. Renewable Energy Integration

- Energy-Efficient Production:

- Adoption of renewable energy sources, such as solar and wind, to power plastic manufacturing facilities.

- Green Chemistry:

- Use of environmentally friendly catalysts and solvents to reduce energy consumption and chemical waste in polymer production.

9. Regional and Market-Specific Trends

- Localization of Production:

- Establishing local production facilities to reduce transportation emissions and enhance supply chain resilience.

- Emerging Markets:

- Rapid growth in demand for plastics in emerging economies, particularly in Asia-Pacific, Latin America, and Africa.

- Sector-Specific Needs:

- Customized plastic materials for sectors like medical devices, automotive, and renewable energy.

10. Challenges and Opportunities

- Scalability of Innovations:

- Scaling up new technologies like bio-based plastics and chemical recycling remains a challenge.

- Cost Competitiveness:

- Balancing sustainability with affordability to meet consumer and industrial demands.

- Technological Breakthroughs:

- Continued research and collaboration among industries, governments, and academia to overcome existing limitations.

Conclusion

The future of plastic raw material production is being redefined by a focus on sustainability, innovation, and efficiency. Advances in bio-based materials, recycling technologies, and high-performance polymers are positioning the industry to meet both regulatory demands and consumer expectations. Collaboration and investment in these emerging technologies will be critical for building a resilient, environmentally friendly plastics industry.

Hashtags

#FutureOfPlastics #PlasticInnovation #AdvancedMaterials #SmartPolymers #SustainablePlastics #GreenMaterials #EcoFriendlyPlastics #CircularEconomy #NextGenMaterials #InnovativePlastics #SmartManufacturing #ReducePlasticWaste #EcoConsciousDesign #PlasticPackagingInnovation #PackagingRevolution