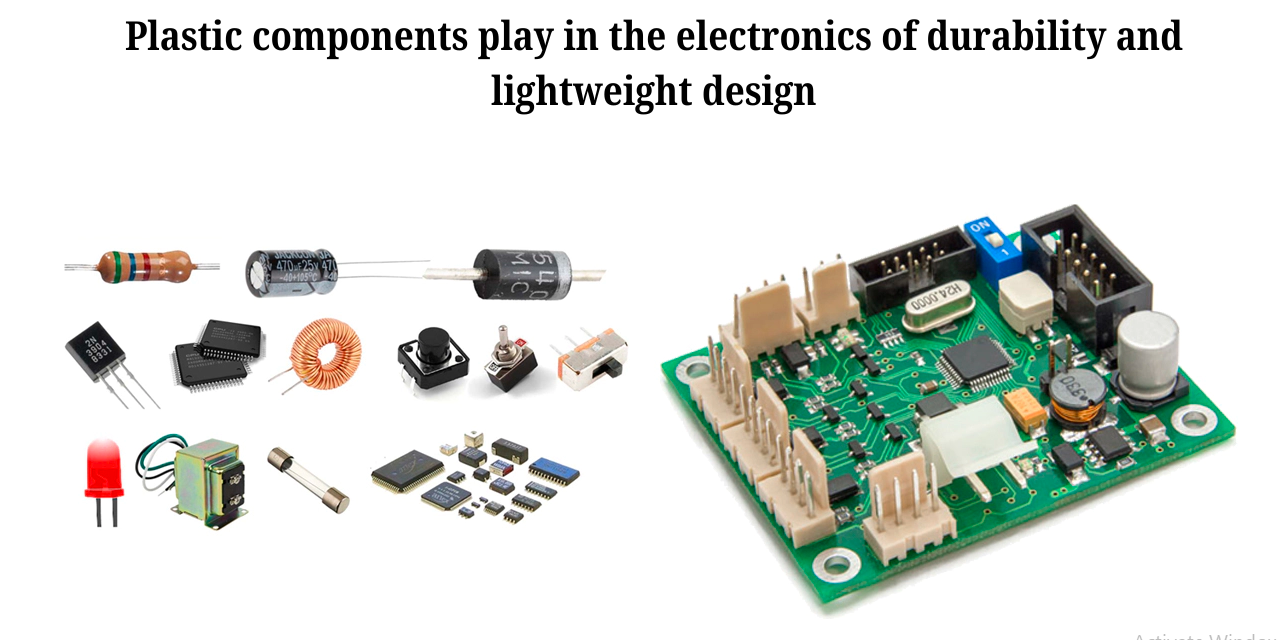

Plastic components play a critical role in the electronics industry by offering solutions that enhance durability, lightweight design, and cost-effectiveness. Plastics are used extensively in the design and manufacturing of electronic devices, from smartphones and computers to home appliances and consumer electronics. The ability of plastics to provide flexibility, protection, and aesthetic appeal is essential in modern electronic products.

1. Durability and Protection

a) Impact Resistance

- Plastic housings and casings are commonly used to protect sensitive electronic components from physical damage. Plastics like polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) are known for their high impact resistance, which helps protect electronics from drops, bumps, and scratches during daily use.

- For example, the outer shells of smartphones and laptops are often made from durable plastics to withstand shocks and impacts while keeping the internal components safe.

b) Chemical Resistance

- Plastics are highly resistant to many chemicals, including acids, oils, and solvents, which can degrade other materials. This is particularly important for circuit boards and electrical enclosures that may come into contact with corrosive substances.

- Polycarbonate and polypropylene are frequently used for protective covers and insulating components because they resist corrosion and chemical degradation.

c) Electrical Insulation

- Plastics serve as excellent electrical insulators, protecting sensitive electrical components from short circuits or electrical damage. Polyamide (PA), polyethylene (PE), and polyurethane (PU) are used in wires, cables, connectors, and switches to ensure safe operation.

- PVC is also widely used for wiring insulation, helping to prevent electrical hazards and ensuring the longevity of electrical circuits.

2. Lightweight Design and Efficiency

a) Reducing Overall Weight

- Plastics are much lighter than traditional materials like metal or glass, which is particularly important in the electronics industry where portability is a key factor.

- The use of plastic components in products like laptops, smartphones, and tablets allows for lighter devices without sacrificing strength or functionality. This results in more ergonomic and user-friendly designs.

- For example, plastic is used in the exterior casing of laptops and smartphones to create lightweight, portable devices that are easier for consumers to handle and carry.

b) Design Flexibility

- Plastics offer significant design flexibility in terms of molding and shaping, which allows electronics manufacturers to create sleek, compact devices that meet modern aesthetic trends. The ability to mold plastics into complex shapes helps in creating thin and lightweight designs without sacrificing structural integrity.

- Plastic enclosures and covers allow for more compact electronic devices while also offering versatility in design features such as ergonomic curves, rounded corners, and integrated button functions.

3. Thermal Management

a) Heat Resistance and Dissipation

- Plastics are often used in heat management applications in electronics, such as in heat sinks, thermal pads, and cooling components. While metals like aluminum are still commonly used for high-performance heat dissipation, plastic materials such as polyamide and polyphenylene sulfide (PPS) are used in applications that require moderate heat resistance.

- Thermally conductive plastics are increasingly used to help dissipate heat from internal circuits and processors. For instance, plastics with added fillers such as graphite or ceramics can be designed to have enhanced heat transfer properties, making them suitable for devices with moderate heat generation.

4. Aesthetic Appeal and Branding

a) Customization and Visual Appeal

- Plastics allow manufacturers to create visually appealing designs that can be customized with a variety of colors, textures, and finishes. Electronics brands often use plastic casings to add aesthetic appeal, enhance branding, and provide a modern look to products.

- For example, the use of glossy plastic finishes in smartphones, tablets, and smartwatches helps create sleek, attractive designs that appeal to consumers looking for both functionality and style.

b) Lightweight Packaging

- In addition to being used in the actual devices, plastics are also used in lightweight packaging for electronics, which not only helps protect the products but also reduces shipping costs and carbon footprint. Plastic packaging can be customized with intricate designs to display product features and branding.

5. Cost-Effectiveness

a) Lower Manufacturing Costs

- Plastics are often more affordable than metals or glass, which helps reduce overall manufacturing costs. Plastics are easier to mold, quicker to produce, and require less energy during production compared to metals or glass.

- The affordability of plastic components allows manufacturers to produce high-quality electronics at a lower cost, which ultimately benefits consumers by keeping the prices of consumer electronics competitive.

b) Efficient Production Processes

- Injection molding and extrusion are common techniques used to produce plastic components in high volumes with precision and efficiency, reducing manufacturing time and costs. These methods are suitable for mass production of components like phone casings, buttons, and connectors.

6. Environmental Impact and Sustainability

a) Recycling and Reusability

- Many plastic materials used in electronics are recyclable, which reduces the environmental impact of electronics manufacturing. Plastics such as polyethylene (PE), polypropylene (PP), and PET can be recycled and reused in the production of new components.

- Manufacturers are increasingly exploring the use of biodegradable plastics or bio-based materials to create more sustainable products.

b) Eco-Friendly Alternatives

- The shift toward bioplastics and recycled plastic in electronic devices is gaining traction as companies look to meet sustainability goals and reduce e-waste. Incorporating these materials in the production of devices like phones, computers, and chargers can reduce the environmental footprint of the electronics industry.

Conclusion

Plastic components play an essential role in the electronics industry by offering numerous benefits, including durability, lightweight design, cost-effectiveness, and aesthetic appeal. Plastics provide solutions that enhance the performance and longevity of electronic devices, such as impact resistance, electrical insulation, thermal management, and chemical resistance. Their design flexibility allows for the production of sleek, compact, and innovative products that meet modern consumer expectations for both function and style. Moreover, the ability to recycle and sustainably source plastics is driving more environmentally responsible practices in the electronics sector, ensuring that these materials remain an essential part of the industry’s future.

Hashtags

#PlasticInElectronics #ElectronicComponents #LightweightDesign #DurablePlastics #PlasticInnovation #TechPackaging #ElectronicsManufacturing #PlasticParts #ElectronicHousing #TechIndustryMaterials #PlasticForElectronics #FlexiblePlastics #SustainableElectronics #PlasticTechComponents #AdvancedPlasticMaterials #EcoFriendlyElectronics #SmartMaterialSolutions