Rotational molding, commonly known as rotomolding, is a plastic manufacturing process used to create hollow, seamless, and durable plastic products. It involves heating plastic resin inside a rotating mold, allowing the material to coat the interior surface evenly. This technique is widely used for producing large, durable, and complex-shaped plastic parts such as water tanks, kayaks, and playground equipment.

Unlike other plastic molding methods, rotational molding does not use high pressure, making it cost-effective and ideal for low to medium production runs.

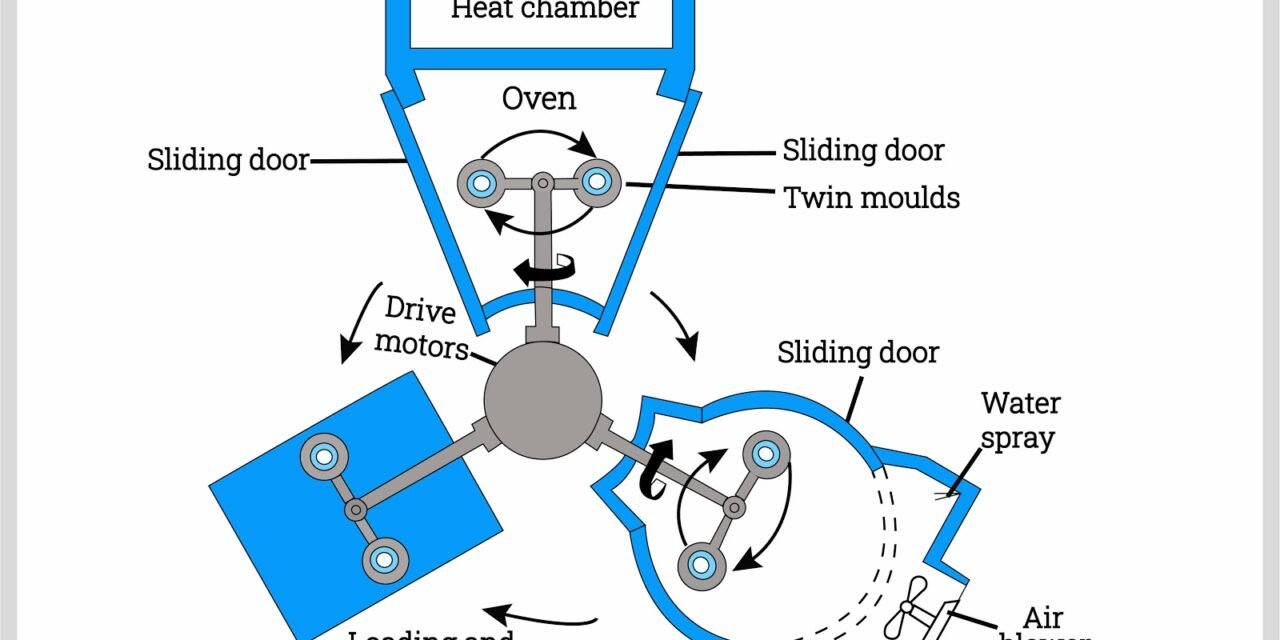

How Rotational Molding Works

- Loading the Mold

- A measured amount of plastic resin (usually in powder form) is placed into a hollow metal mold.

- Heating and Rotating

- The mold is heated inside an oven while being rotated along two perpendicular axes.

- The plastic melts and evenly coats the interior surface of the mold.

- Cooling

- The mold is cooled using air or water, allowing the plastic to solidify into its final shape.

- Unloading the Mold

- The mold is opened, and the finished part is removed. The process then repeats for the next cycle.

How Rotational Molding Differs from Other Plastic Molding Processes

1. Material Distribution and Uniformity

- Rotational molding creates even wall thickness without weak points, unlike injection molding, which may have stress-prone areas due to pressure.

- It produces seamless parts, unlike blow molding, where seams can weaken the final product.

2. Cost and Tooling Expenses

- Lower tooling costs than injection molding, making it ideal for custom or small production runs.

- No high-pressure machinery required, unlike injection molding, which involves expensive steel molds.

3. Complexity and Customization

- Suitable for large, hollow, and complex shapes, which injection molding and compression molding struggle to produce.

- Unlike thermoforming, which is mainly for thin sheets, rotational molding allows for thicker and more durable parts.

4. Part Size and Hollow Structures

- Ideal for large hollow objects like tanks, unlike injection molding, which is better for solid or small precision parts.

- More durable and stress-free than blow molding, which can leave weak seams.

5. Production Speed and Efficiency

- Slower production cycle than injection molding, as it takes longer for the plastic to coat, melt, and cool.

- Best for low-to-medium volume production, whereas injection molding is better for mass production.

6. Strength and Durability

- Produces impact-resistant, stress-free parts, making it preferable for outdoor and industrial applications.

- Unlike injection-molded parts, rotomolded parts have no pressure-induced weak points.

Common Applications of Rotational Molding

Rotational molding is widely used for:

- Water tanks and chemical storage containers

- Playground equipment and slides

- Boats, kayaks, and outdoor furniture

- Traffic barriers and road safety equipment

- Agricultural bins and fuel tanks

Conclusion

Rotational molding is a versatile and cost-effective plastic manufacturing process for hollow and large plastic products. While it has a slower cycle time and is less precise for fine details compared to injection molding, it excels in seamless durability, stress-free parts, and low tooling costs. Industries that require strong, lightweight, and complex plastic components often prefer rotational molding over other methods. By understanding its advantages and differences, manufacturers can choose the best molding technique for their needs.

Hashtags

#RotationalMolding #RotoMolding #PlasticMolding #PlasticManufacturing #MoldingTechnology #CustomMolding #IndustrialMolding #PlasticParts #PlasticProduction #RotomoldedProducts #ManufacturingInnovation #SustainablePlastics #EcoFriendlyMolding #SmartManufacturing #PlasticIndustry #MadeInUSA #IndustryExperts #ProductDevelopment #EngineeringDesign #CustomManufacturing #PlasticEngineering #MoldingSolutions #AdvancedManufacturing #QualityAssurance #SupplyChainManagement #InnovationInManufacturing