Packaging tubes in the plastics and rubber industry are widely used for products like cosmetics, pharmaceuticals, food, and industrial applications. The choice of materials is crucial as it affects the durability, aesthetic appeal, barrier properties, and recyclability of the tubes. The primary materials used in manufacturing packaging tubes include various types of plastics, rubber derivatives, and composites. Here’s a detailed look at these materials:

1. Plastics

Plastics dominate the packaging tube market due to their versatility, lightweight properties, and cost-effectiveness. The most common types of plastics used are:

A. Polyethylene (PE)

- Types:

- High-Density Polyethylene (HDPE):

- Provides excellent stiffness and durability.

- Commonly used for rigid tubes like toothpaste or pharmaceutical ointments.

- Low-Density Polyethylene (LDPE):

- Flexible and squeezable, ideal for cosmetic tubes like moisturizers and lotions.

- High-Density Polyethylene (HDPE):

- Advantages:

- Lightweight and cost-effective.

- Resistant to moisture and many chemicals.

- Recyclable in mono-material designs.

- Applications:

- Toothpaste tubes, skincare products, and pharmaceuticals.

B. Polypropylene (PP)

- Properties:

- High resistance to heat, chemicals, and fatigue.

- Offers transparency or opaque options.

- Advantages:

- Suitable for high-temperature processes like sterilization.

- Durable and maintains structural integrity.

- Applications:

- Pharmaceutical tubes, food-grade packaging, and industrial products.

C. Polyethylene Terephthalate (PET)

- Properties:

- Excellent transparency and glossy finish.

- Superior barrier properties for oxygen and moisture.

- Advantages:

- Recyclable and used for high-end cosmetic and food tubes.

- Retains product freshness longer than other plastics.

- Applications:

- Premium cosmetic tubes, food products, and gels.

D. Ethylene Vinyl Acetate (EVA)

- Properties:

- Highly flexible and soft material.

- Offers good adhesion to other materials.

- Advantages:

- Used as a co-extruded layer for flexibility and squeezability.

- Applications:

- Specialty tubes for medical or adhesive products.

2. Rubber and Elastomers

Rubber-based materials are less common than plastics but are used in specialized applications where flexibility and durability are critical.

A. Thermoplastic Elastomers (TPE)

- Properties:

- Combines the elasticity of rubber with the processability of plastics.

- Soft and flexible with excellent impact resistance.

- Advantages:

- Ideal for squeezable tubes requiring a rubber-like feel.

- Applications:

- Pharmaceutical ointments, specialty adhesives, and industrial sealants.

B. Natural and Synthetic Rubber

- Properties:

- High flexibility and resistance to chemical degradation.

- Limited use due to cost and lower recyclability.

- Applications:

- Specialty industrial tubes for sealants or lubricants.

3. Composite Materials

Composite materials are used for multi-layer tubes to combine the benefits of various materials, such as barrier protection, aesthetics, and structural strength.

A. Multi-Layer Plastic Tubes

- Structure:

- Often made of co-extruded layers of LDPE, HDPE, PET, or EVOH (Ethylene Vinyl Alcohol).

- EVOH serves as a barrier layer for oxygen and aroma protection.

- Advantages:

- Offers excellent barrier properties for sensitive products.

- Customizable for specific requirements.

- Applications:

- High-end cosmetics, food pastes, and pharmaceutical gels.

B. Laminated Tubes

- Structure:

- Consists of layers of plastic (e.g., PE or PP) and aluminum foil or other barrier materials.

- Advantages:

- Combines the flexibility of plastics with the barrier properties of metals.

- Resistant to light, oxygen, and moisture.

- Applications:

- Toothpaste, hair dyes, and specialty pharmaceuticals.

C. Plastic-Aluminum Hybrid Tubes

- Structure:

- Inner aluminum layer for barrier protection, surrounded by plastic layers for flexibility and durability.

- Advantages:

- Superior protection for sensitive or volatile products.

- Applications:

- Pharmaceutical tubes, food packaging (e.g., sauces), and adhesives.

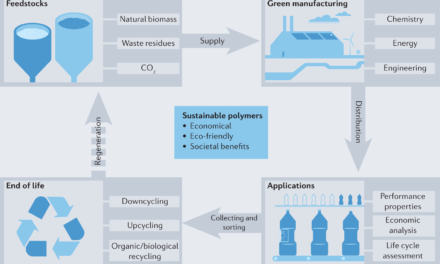

4. Biodegradable and Sustainable Materials

In response to environmental concerns, biodegradable and eco-friendly materials are increasingly used for packaging tubes.

A. Polylactic Acid (PLA)

- Properties:

- Derived from renewable resources like corn starch or sugarcane.

- Fully compostable under industrial conditions.

- Advantages:

- Eco-friendly alternative to traditional plastics.

- Applications:

- Skincare products, travel-sized toiletries, and sustainable food packaging.

B. Sugarcane-Derived Polyethylene (Bio-PE)

- Properties:

- Similar to conventional PE but made from renewable sugarcane.

- Advantages:

- Reduces carbon footprint while maintaining plastic-like properties.

- Applications:

- Toothpaste and cosmetic tubes for eco-conscious brands.

C. Starch-Based Composites

- Properties:

- Blended with other materials to create partially biodegradable tubes.

- Advantages:

- Suitable for short-term use and reduces reliance on petroleum-based plastics.

- Applications:

- Travel-sized and disposable packaging.

5. Metal-Plastic Hybrid Tubes

- Structure:

- Combination of aluminum or tin for strength and barrier properties with plastic for flexibility.

- Advantages:

- Exceptional protection against light and oxygen while offering ease of use.

- Applications:

- Premium cosmetics, pharmaceutical ointments, and specialty adhesives.

Emerging bioplastics, multi-layer composites, and metal-plastic hybrids represent the future of packaging tubes, as industries balance performance, aesthetic appeal, and sustainability in their designs.