Polymer manufacturing raises several environmental concerns, particularly regarding the use of fossil fuels for raw materials, energy-intensive production processes, and the disposal of polymer waste. As awareness of plastic pollution and the carbon footprint of polymer production grows, manufacturers are increasingly focusing on sustainable practices to reduce environmental impacts. Here’s an overview of the key environmental concerns and how manufacturers are addressing them:

1. Resource Depletion and Fossil Fuel Dependency

Concern:

- Most polymers are derived from petrochemicals sourced from crude oil and natural gas, which are non-renewable resources. This creates concerns about resource depletion, and the environmental impacts of extracting and refining fossil fuels.

Solution:

- Bio-Based Polymers: Manufacturers are shifting towards bio-based polymers, which are derived from renewable resources like corn, sugarcane, potatoes, and cellulose. For example, polylactic acid (PLA) is made from corn starch, while polyhydroxyalkanoates (PHA) are produced by bacteria using plant sugars. These polymers offer a more sustainable alternative to petroleum-based plastics.

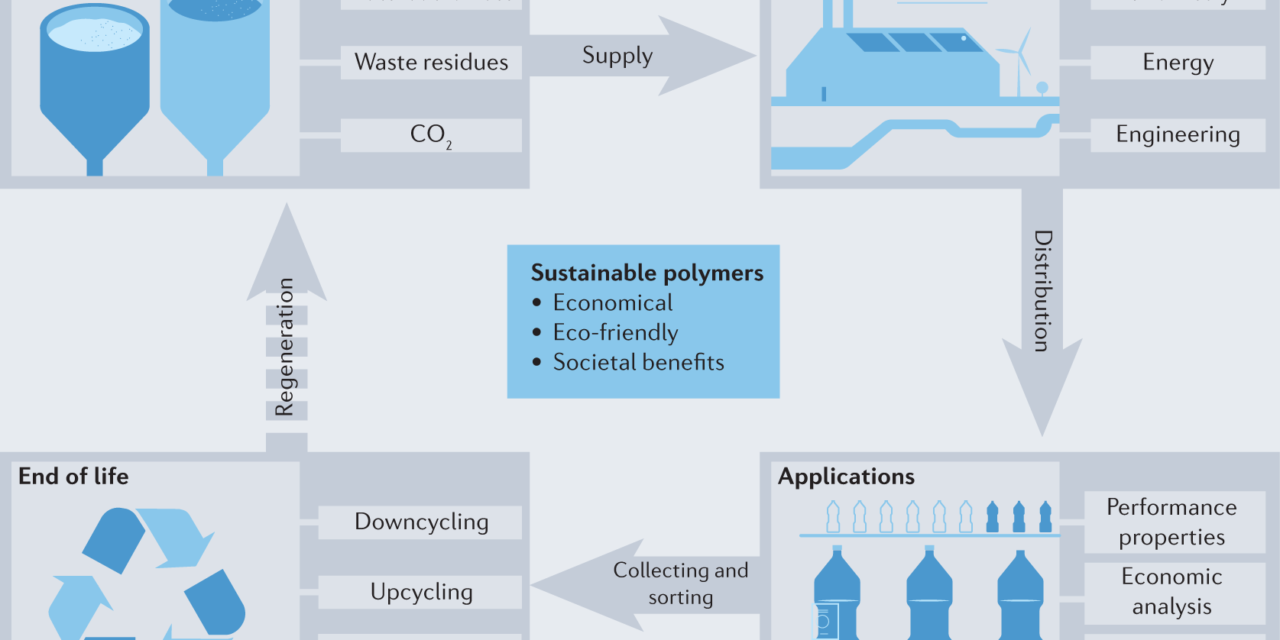

- Circular Economy: The promotion of a circular economy in polymer production encourages the use of recycled materials instead of virgin petrochemical resources. By increasing recycling rates and reusing plastics in new products, manufacturers reduce their reliance on fossil fuels.

2. Energy Consumption and Greenhouse Gas Emissions

Concern:

- Polymer production is energy-intensive, requiring high temperatures and pressures for processes like polymerization, extrusion, and injection molding. This results in significant carbon emissions and contributes to climate change.

Solution:

- Energy Efficiency Improvements: Manufacturers are investing in more energy-efficient production methods, such as optimizing heating processes, using waste heat recovery systems, and improving machine efficiency.

- Renewable Energy: The adoption of renewable energy sources, such as solar, wind, and biomass, in production facilities can help lower the carbon footprint of polymer manufacturing. Some manufacturers are already transitioning to green energy to power their operations.

- Alternative Polymerization Methods: Developing more energy-efficient polymerization methods, including the use of milder processing conditions and low-energy catalysts, is helping reduce overall energy demand in polymer manufacturing.

3. Plastic Waste and Landfill Overflow

Concern:

- Many polymers, especially single-use plastics, are non-biodegradable and can persist in the environment for hundreds of years. Plastic pollution in oceans, rivers, and landfills is a growing concern, harming wildlife and contributing to ecosystem disruption.

Solution:

- Recycling Programs: Manufacturers are focusing on improving recycling systems by developing easier-to-recycle materials and investing in more efficient sorting and collection technologies. This includes innovations such as chemical recycling and closed-loop recycling, which allows plastics to be returned to their original monomers and reused.

- Biodegradable Plastics: The development and use of biodegradable plastics, such as PLA and PHA, are being encouraged as alternatives to traditional petroleum-based plastics. These materials degrade more easily in composting or landfill environments and reduce the environmental impact of plastic waste.

- Product Design for Recycling: Manufacturers are increasingly designing products with recyclability in mind. This includes monomaterial packaging, which is easier to recycle compared to multi-material packaging, and reducing the use of additives that hinder recycling.

4. Toxicity and Chemical Pollution

Concern:

- The production of synthetic polymers often involves the use of hazardous chemicals like solvents, plasticizers, additives, and monomers. These chemicals can cause air, water, and soil pollution if not properly handled or disposed of.

Solution:

- Green Chemistry: The application of green chemistry principles focuses on reducing the use of harmful chemicals in polymer production. This includes developing safer monomers, biodegradable plasticizers, and non-toxic stabilizers that do not contribute to environmental harm.

- Closed-Loop Manufacturing: Some manufacturers are adopting closed-loop manufacturing systems that minimize waste and the release of toxic chemicals into the environment. By recycling solvents and reusing chemicals within the system, manufacturers can reduce their environmental impact.

5. End-of-Life Management and Recycling Challenges

Concern:

- Even though recycling rates for some polymers (e.g., PET, HDPE) have increased, many plastics still end up in landfills or incinerators because of issues like contamination, limited infrastructure, and complex polymer types that are difficult to recycle.

Solution:

- Design for Recycling: Polymer manufacturers are designing products with easier disassembly, simpler material structures, and clear labeling to make recycling easier and more efficient. This includes eliminating multi-layered packaging and non-recyclable additives.

- Chemical Recycling: Emerging technologies such as chemical recycling (e.g., pyrolysis, depolymerization) are enabling the recycling of difficult-to-recycle materials like multi-layer packaging and thermosets. These methods break polymers down into their basic chemical components and regenerate them into new polymers, providing a higher-quality recycled material.

- Extended Producer Responsibility (EPR): Many countries have implemented EPR regulations, which hold manufacturers responsible for the entire lifecycle of their products, including post-consumer waste. This encourages companies to develop products that are easier to recycle and participate in take-back schemes.

6. Water Usage and Pollution

Concern:

- Polymer manufacturing processes can require significant amounts of water for cooling and cleaning, contributing to water scarcity and pollution from runoff or wastewater containing chemicals and polymers.

Solution:

- Water Recycling: Manufacturers are increasingly investing in water recycling systems to treat and reuse water within the production process. This reduces the need for fresh water and minimizes the impact on local water resources.

- Zero-Discharge Systems: Some companies are adopting zero-discharge systems, where all wastewater is treated, purified, and reused within the facility, ensuring that harmful chemicals do not enter local waterways.

Polymer manufacturing is facing significant environmental challenges, including resource depletion, plastic waste, chemical pollution, and energy consumption. However, the industry is making strides in addressing these concerns through sustainable practices such as the development of bio-based polymers, improvements in recycling technologies, and the adoption of green chemistry principles.