Switching from plastic to tin containers for industrial packaging has significant cost implications that depend on factors such as material costs, manufacturing processes, transportation, recyclability, and product requirements. While tin offers superior durability, recyclability, and protection, it is generally more expensive than plastic, especially for high-volume, low-margin applications. Here’s a breakdown of the cost implications:

1. Material Costs

Tin Containers

- Higher Material Costs:

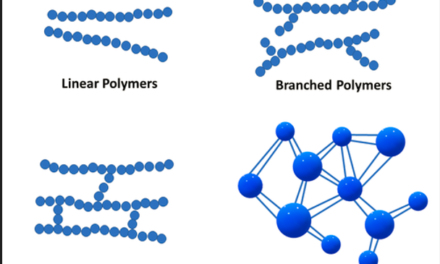

- Tin (steel or aluminum) is more expensive than most plastic resins like PET, HDPE, or PP.

- Costs are influenced by global prices for metals (iron ore for steel, bauxite for aluminum) and can fluctuate based on supply chain dynamics.

- Recycled Content:

- Tin containers can utilize a high percentage of recycled material, which may lower costs over time, particularly in regions with advanced recycling systems.

Plastic Containers

- Lower Material Costs:

- Plastic resins are typically less expensive to produce and widely available, making them a cost-effective option for industrial packaging.

- Prices are influenced by oil and natural gas markets, as plastics are petroleum-based.

- Cost Per Unit:

- Plastic is often the preferred choice for high-volume, low-cost applications due to its lower upfront costs.

2. Manufacturing Costs

Tin Containers

- High Energy Requirements:

- Producing tin containers involves energy-intensive processes like smelting, rolling, and coating, increasing production costs.

- Advanced Coatings:

- Food-safe or corrosion-resistant coatings (e.g., BPA-free) add to the manufacturing expense.

- Customization:

- Tin containers with specialized designs, embossing, or printing increase costs further.

- Economies of Scale:

- Tin containers are less cost-effective for smaller production runs due to higher setup costs.

Plastic Containers

- Lower Energy Usage:

- Plastic manufacturing (e.g., injection molding, blow molding) is less energy-intensive than metal production.

- High Production Efficiency:

- Plastic containers are faster and cheaper to manufacture in high volumes, benefiting from economies of scale.

3. Transportation Costs

Tin Containers

- Higher Weight:

- Tin containers are heavier than plastic, resulting in higher shipping and handling costs.

- Impact on Logistics:

- Increased fuel consumption and transport fees, especially for long-distance or bulk shipments.

Plastic Containers

- Lightweight:

- Plastic containers are lighter, reducing transportation costs and emissions.

- Stackability:

- Plastic containers are often more stackable and space-efficient, further lowering logistics costs.

4. Storage and Handling Costs

Tin Containers

- Durability Reduces Breakage:

- Tin’s rigidity minimizes losses from breakage or deformation during storage and handling, which can offset higher initial costs in certain industries.

- Airtight and Long-Term Storage:

- Tin containers are ideal for products requiring extended storage, potentially reducing spoilage and waste.

Plastic Containers

- Less Durable:

- Plastic containers are more prone to deformation, punctures, or cracking under pressure, leading to higher potential for product losses.

5. Lifecycle Costs

Tin Containers

- Reusability:

- Tin containers are often reusable, particularly in industrial settings like chemical or paint storage, reducing long-term costs.

- High Recycling Value:

- Tin is infinitely recyclable without quality degradation, and recycled tin or aluminum has significant market value, partially offsetting initial costs.

- Environmental Compliance:

- Regulations favoring recyclable materials can make tin a more attractive choice in regions with stringent sustainability requirements, potentially avoiding fines or compliance costs.

Plastic Containers

- Low Recycling Rates:

- Plastics often degrade during recycling (downcycling) and may require additional costs for disposal in non-recyclable scenarios.

- Environmental Impact:

- Costs associated with regulatory compliance, environmental taxes, or consumer backlash against single-use plastics may increase the total cost of using plastic.

6. Product-Specific Cost Implications

Industrial Chemicals and Hazardous Materials

- Tin Containers:

- Offer superior resistance to chemical interactions and corrosion when lined with specialized coatings, justifying the higher cost for products like solvents, adhesives, or oils.

- Reduce risk of leakage or contamination, minimizing potential liabilities.

- Plastic Containers:

- More cost-effective for non-corrosive or short-term applications but may require thicker walls or specialized resins for chemical resistance, increasing costs.

Food and Pharmaceutical Products

- Tin Containers:

- Ensure product safety and extended shelf life due to excellent barrier properties, reducing costs associated with spoilage or recalls.

- Plastic Containers:

- Cheaper for short-term storage or refrigerated items but require additives or multi-layer designs to match tin’s protective qualities, which can increase costs.

7. Transition and Implementation Costs

Switching Challenges

- Equipment and Tooling:

- Transitioning to tin containers may require significant investment in new manufacturing equipment, particularly for companies currently set up for plastic production.

- Training and Process Adjustments:

- Staff training and production line adjustments increase short-term expenses.

Cost Mitigation Strategies

- Hybrid Packaging:

- Combining tin with plastic or rubber components (e.g., metal containers with plastic spouts or lids) offers a balance between cost, functionality, and sustainability.

- Recycled Tin:

- Utilizing recycled tin or aluminum reduces material costs and improves sustainability.

8. Market and Consumer Considerations

Perceived Value

- Tin Containers:

- Often associated with premium or high-value products, allowing manufacturers to justify higher price points.

- Example: A paint manufacturer may use tin for premium-quality products and plastic for budget lines.

Regulatory Trends

- Plastic Bans and Restrictions:

- Increasing regulations against single-use plastics in various regions may raise compliance costs for plastic packaging, shifting cost advantages in favor of tin containers.

Switching from plastic to tin containers for industrial packaging increases upfront costs due to higher material, manufacturing, and transportation expenses. However, tin offers long-term benefits in durability, recyclability, and sustainability, which may offset some costs, particularly for products requiring extended shelf life, superior protection, or compliance with environmental regulations.