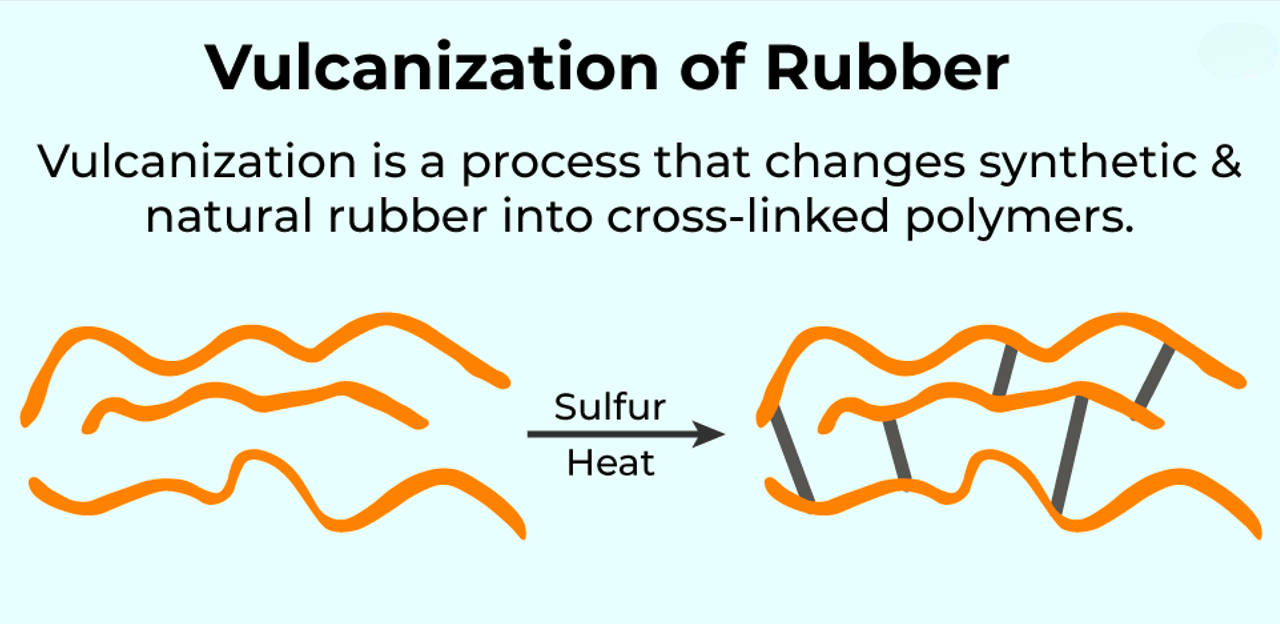

Vulcanization is a crucial process used to enhance the durability, elasticity, and overall performance of rubber products. It involves chemically cross-linking the polymer chains in rubber using a vulcanizing agent, most commonly sulfur, under heat and pressure. This process changes the rubber’s molecular structure, making it more elastic, strong, and resistant to various forms of physical and environmental degradation.

Here’s how vulcanization improves the durability and elasticity of rubber products:

1. Cross-Linking Polymer Chains

- During vulcanization, sulfur atoms form cross-links between individual polymer chains of rubber. These sulfur links create a three-dimensional network structure, which restricts the movement of polymer chains relative to each other.

- Effect on Durability:

- The cross-linked structure significantly improves the strength and resilience of the rubber, making it less prone to wear and tear. The rubber becomes more resistant to deformation, abrasion, and tearing under stress, which enhances its longevity in applications like tires, gaskets, and seals.

- Effect on Elasticity:

- The sulfur cross-links allow the rubber to return to its original shape after being stretched or compressed, resulting in improved elasticity. This makes vulcanized rubber ideal for applications that require flexibility, such as automotive parts (e.g., suspension bushings), footwear (e.g., soles), and medical devices (e.g., catheters).

2. Improved Temperature and Weather Resistance

- Heat Resistance: Vulcanized rubber can withstand higher temperatures without losing its shape or becoming soft, making it ideal for applications like engine seals or brake components that are exposed to high heat.

- Weathering Resistance: The cross-linked structure also makes vulcanized rubber more resistant to environmental factors such as UV radiation, ozone, and humidity. It prevents the rubber from becoming brittle or cracking when exposed to outdoor conditions. This is particularly important for products like roofing materials, automotive tires, and seals that are constantly exposed to the elements.

3. Enhanced Chemical and Oil Resistance

- Vulcanization improves the chemical resistance of rubber. Unvulcanized rubber is more susceptible to degradation when exposed to oils, solvents, and various chemicals. Cross-linking makes the rubber less likely to absorb these substances, thus enhancing its chemical resistance and making it more suitable for applications where the rubber is in contact with fuel, oils, and chemicals (e.g., fuel hoses, gaskets).

- The resulting tougher surface can resist swelling or deterioration, which is especially important for automotive and industrial applications where rubber components face exposure to harsh substances.

4. Improved Physical Properties

- Hardness: Vulcanization increases the hardness of rubber, making it more suitable for applications that require strength and abrasion resistance. The rubber becomes tougher and more resilient, able to resist deformation when under pressure.

- Compression Set Resistance: Vulcanized rubber is more resistant to permanent deformation under compressive forces. This property, known as compression set resistance, ensures that rubber products like O-rings and gaskets maintain their seal integrity and shape under high-pressure and high-temperature conditions.

- Tensile Strength: The process of vulcanization increases the tensile strength of rubber, allowing it to withstand more substantial stretching and loading without breaking or tearing. This is critical for high-stress applications like automotive tires and industrial belts.

5. Variability in Properties through Vulcanization Control

- The degree of vulcanization (i.e., how much sulfur is used and the temperature and time of the process) can be controlled to achieve different rubber hardness and flexibility. This allows manufacturers to customize the properties of the rubber for specific applications. For example:

- Soft vulcanized rubber is used for gaskets and seals that need flexibility and compression properties.

- Hard vulcanized rubber is used for automotive tires and industrial applications where strength and abrasion resistance are essential.

6. Types of Vulcanization Methods

- Hot Vulcanization: The most common method, where rubber is heated with sulfur (along with other additives) in a mold. This is the most common method used for producing tires, rubber seals, and other components.

- Cold Vulcanization: In some applications, cold vulcanization is used, where the curing process occurs at room temperature with peroxide or other curing agents. This method is more common for producing products that don’t require as high-temperature processing or for situations where precise molding is needed.

Conclusion

Vulcanization is a crucial process that significantly enhances the elasticity, strength, and durability of rubber products. The cross-linking of polymer chains through vulcanization makes rubber more resistant to heat, weathering, chemicals, and abrasion, while also improving its flexibility and tensile strength. This process is essential for ensuring the reliability and longevity of rubber products used in demanding industries such as automotive, aerospace, industrial, and medical applications. The ability to control the degree of vulcanization also allows manufacturers to tailor rubber properties for specific applications, making it one of the most versatile and valuable processes in rubber manufacturing.

Hashtags

#Vulcanization #RubberCuring #VulcanizedRubber #RubberProcessing #CuringTechnology #EnhancedDurability #ElasticityBoost #ToughAndFlexible #RubberPerformance #DurableMaterials #RubberTechnology #MaterialInnovation #AdvancedProcessing #PolymerEngineering #RubberScience #SustainableProcessing #EcoFriendlyRubber #EfficientManufacturing #GreenTechnology #RubberSustainability #IndustrialRubber #AutomotiveMaterials #AerospaceRubber #DurableGoods #EngineeringApplications #MaterialScience #PolymerTechnology #RubberIndustry #InnovativeMaterials #PerformanceMaterials