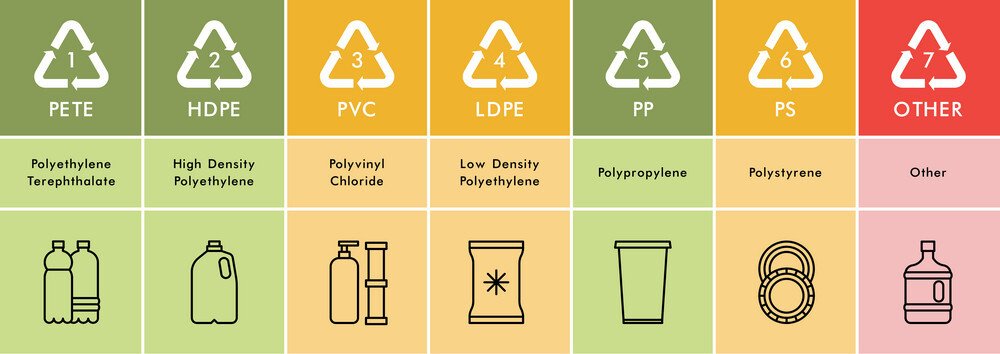

Recyclability is a crucial factor when evaluating the environmental impact of different plastic packaging materials. The ease and efficiency of recycling vary significantly between different types of plastics, as their chemical structure and properties determine how well they can be processed into new products. Here’s a comparison of the recyclability of common plastic packaging materials like PET, HDPE, and PVC:

1. Polyethylene Terephthalate (PET or PETE)

- Recyclability:

- PET is one of the most widely recycled plastics in the world and has an established recycling infrastructure.

- Recycling Process: PET can be processed through mechanical recycling, where it is cleaned, melted, and reformed into new products, such as new bottles, clothing fibers, and carpet fibers. It is also used in food packaging after proper reprocessing.

- Closed-loop Recycling: PET can be recycled into new PET bottles in a closed-loop system, which is highly efficient and ideal for beverage containers.

- Advantages:

- PET has a high recycling rate compared to other plastics, particularly in countries with established recycling systems (e.g., Europe and North America).

- Recycled PET (rPET) is used widely in the textile industry, creating fleece jackets, carpet padding, and even new bottles.

- Challenges:

- While PET is widely recycled, contamination (e.g., food or drink residue) can reduce the effectiveness of the recycling process.

- The quality of recycled PET may be lower than virgin PET, particularly in food-grade applications, though recent advancements in recycling technology are improving this.

2. High-Density Polyethylene (HDPE)

- Recyclability:

- HDPE is also highly recyclable and widely accepted by most curbside collection programs.

- Recycling Process: HDPE is sorted, shredded, and melted down to create new products like plastic lumber, recycled pipes, and recycled containers. It is relatively easy to process compared to other plastics.

- Closed-loop Recycling: While HDPE recycling is common, it is typically recycled into non-food-grade products, as HDPE can lose some of its structural integrity and purity after multiple cycles.

- Advantages:

- High recycling rate: HDPE has one of the highest recycling rates of any plastic. It is durable and can be used in a wide variety of applications even when recycled.

- Good material strength: Recycled HDPE (rHDPE) is strong and durable, which makes it ideal for products like gardening products, trash bags, and piping.

- Challenges:

- As with PET, contamination can affect the recycling process, and colorants or other additives can reduce the material’s recyclability.

- Recycled HDPE is not typically used in food-grade applications because the recycling process can lead to impurities in the material.

3. Polyvinyl Chloride (PVC)

- Recyclability:

- PVC is more difficult to recycle than PET and HDPE. While technically recyclable, PVC is not as widely accepted in municipal recycling systems.

- Recycling Process: The recycling process for PVC involves sorting, cleaning, and grinding it into chips or powder, which can then be reprocessed into new products such as tiles, flooring, or PVC pipes. However, this process can release harmful chlorine compounds during thermal degradation, making PVC recycling more hazardous.

- Advantages:

- PVC is strong and durable, making it a suitable material for long-lasting applications like pipes and medical equipment.

- Some types of rigid PVC (used in pipes or window profiles) can be recycled, though they are usually repurposed for non-food-related products.

- Challenges:

- Contamination and additives: PVC often contains additives such as plasticizers, stabilizers, and colorants, which complicate the recycling process. These additives can create contamination, making it harder to produce high-quality recycled products.

- Limited recycling infrastructure: The infrastructure for PVC recycling is not as widespread as for PET and HDPE. In many areas, PVC packaging is not accepted in curbside recycling programs.

- Toxic emissions: When burned, PVC can release toxic gases such as dioxins and hydrochloric acid, posing serious environmental and health risks.

4. Other Considerations

- Closed-loop Recycling: PET has a significant advantage in closed-loop recycling, meaning it can be continuously recycled into the same product (e.g., new PET bottles). HDPE can also be recycled effectively, though it is typically used for non-food products after recycling.

- Recycling Challenges: PVC is more problematic to recycle due to its toxic additives and the difficulty in breaking it down into usable materials. This results in lower recycling rates and more complex recycling processes.

- Environmental Impact: PET and HDPE are much less harmful to the environment when recycled compared to PVC, which can release toxic emissions when improperly handled or incinerated.

- PET and HDPE are the easiest and most widely recycled plastics, with well-established recycling systems, especially in regions with high recycling rates. PET is particularly advantageous in closed-loop recycling, while HDPE offers high durability and versatility in recycled applications.

- PVC, on the other hand, is much harder to recycle due to the complex additives it contains, its limited recycling infrastructure, and its potential for toxic emissions. As a result, PVC packaging is less commonly recycled compared to PET and HDPE.