The selection of a specific polymer for a particular application or industry is influenced by a range of factors that determine the performance, cost-effectiveness, and suitability of the polymer for the intended use. Different industries require polymers with specific mechanical, thermal, chemical, and processing properties. Here’s a breakdown of the key factors that determine the selection of a polymer:

1. Mechanical Properties

- Strength: The polymer needs to be strong enough to withstand the mechanical stresses and loads it will encounter in its application. For instance, automotive components require polymers with high tensile strength and impact resistance.

- Elasticity: If the application requires the polymer to return to its original shape after deformation, such as in seals or gaskets, materials like elastomers (e.g., rubber) are selected.

- Hardness: Some applications require polymers to be hard and resistant to abrasion, such as in medical devices or engineering plastics. Polymers like polycarbonate (PC) and polyetheretherketone (PEEK) offer high hardness.

- Creep Resistance: For applications where polymers are under sustained load or stress (e.g., in construction or automotive), the material must resist creep (slow deformation over time). Thermosetting plastics like epoxies often have better creep resistance than thermoplastics.

2. Thermal Properties

- Melting Temperature: The polymer must be able to withstand the operating temperature of the application without losing its structural integrity. For high-temperature applications, such as in automotive engines or electrical insulation, polymers like polyphenylene sulfide (PPS) and PEEK are chosen due to their high thermal stability.

- Thermal Conductivity: In applications where heat dissipation is important, such as electronics and automotive cooling systems, polymers with good thermal conductivity (e.g., polyamide (PA)) are selected. Conversely, materials with low thermal conductivity, like polyethylene (PE), are chosen for insulation.

- Heat Deflection Temperature: This is important in applications where the polymer will experience elevated temperatures, such as automotive parts or cooking appliances. Nylon and polycarbonate are selected for their heat deflection properties.

3. Chemical Resistance

- Exposure to Chemicals: In applications where the polymer will come into contact with chemicals, oils, fuels, or solvents, the material must have chemical resistance. For example, nitrile rubber (NBR) is selected for fuel hoses due to its oil resistance, while PVC and PTFE are chosen for piping and valves in chemical processing applications.

- Environmental Stress Cracking: Some polymers may suffer from stress cracking when exposed to certain chemicals. This must be considered when selecting polymers for gaskets, seals, or tanks.

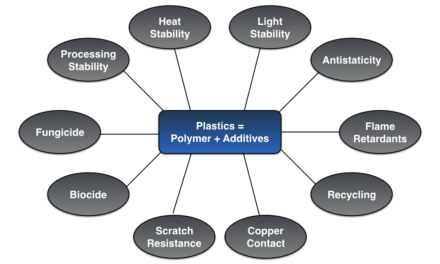

4. Processing and Manufacturing Considerations

- Ease of Processing: The polymer must be compatible with the manufacturing process used in the industry, whether it’s injection molding, extrusion, blow molding, or rotational molding. For example, polypropylene (PP) is ideal for injection molding due to its ease of processing and low melting point.

- Viscosity and Flowability: The viscosity of the polymer in its molten state influences the ease with which it can be processed. Polymers with low viscosity are ideal for molding and extrusion processes that require rapid flow into molds (e.g., PVC).

- Cost and Availability: The cost of the polymer and the availability of raw materials also influence the selection. Polyethylene (PE) and polypropylene (PP) are relatively inexpensive and widely available, making them ideal for mass-produced items such as packaging and consumer goods.

5. Environmental and Sustainability Factors

- Biodegradability: For environmentally conscious applications, such as food packaging or medical disposables, biodegradable polymers like polylactic acid (PLA), derived from renewable resources like corn starch, are often chosen to minimize environmental impact.

- Recyclability: Many industries, especially in packaging and electronics, prioritize polymers that are easily recycled. Polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) are often used for their recyclability and circular economy potential.

- Sustainability: In addition to biodegradability and recyclability, sustainability includes considering the carbon footprint of the polymer’s production. The use of bio-based polymers or recycled polymers helps reduce reliance on petroleum-based materials.

6. Electrical Properties

- Electrical Insulation: Polymers used in electrical components, such as cables, connectors, and circuit boards, must possess good electrical insulation properties. For example, polyvinyl chloride (PVC) and polyethylene (PE) are commonly used for wires and insulation due to their dielectric strength.

- Electromagnetic Interference (EMI) Shielding: In some electronic applications, the polymer may need to provide EMI shielding. Polymers like carbon-filled polyethylene (PE) or polycarbonate (PC) are often used to block or absorb electromagnetic radiation.

7. Aesthetic and Surface Properties

- Appearance: In applications where aesthetics are important (e.g., consumer electronics, automotive interiors, packaging), polymers need to be chosen for their color, clarity, and finish. For instance, polycarbonate (PC) is chosen for transparent parts like lenses or displays because it has excellent optical clarity.

- Surface Texture: Some polymers are selected for their ability to be molded with specific surface textures, such as smooth, matte, or textured finishes, for products like consumer goods or decorative items.

8. Specific Industry Requirements

- Automotive Industry: Polymers like polypropylene (PP), nylon (PA), and polyurethane (PU) are commonly used in the automotive industry due to their high strength, heat resistance, and impact resistance. The materials used for interior components, bumpers, dashboard parts, and seating require lightweight and durable properties to improve fuel efficiency and safety.

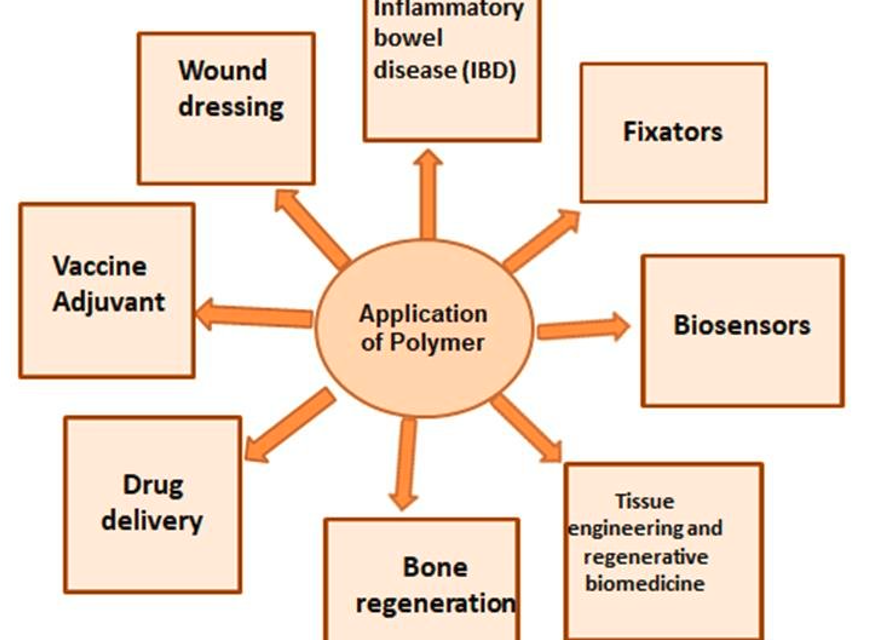

- Medical Industry: Polymers used in medical devices must be biocompatible, sterilizable, and resistant to chemical degradation. Polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), and silicone rubber are common choices for medical tubing, syringes, and implants. Biodegradable polymers may also be used for sutures or drug delivery systems.

- Packaging Industry: Polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) are popular in packaging because they are lightweight, cost-effective, and can be easily molded into a variety of forms like bags, bottles, and films. Barrier properties such as moisture, oxygen, and UV resistance are important considerations for the food packaging industry.

Conclusion

The selection of a specific polymer for a particular application or industry is determined by a combination of mechanical, thermal, chemical, environmental, and processing properties required by the end product. Polymers need to meet performance standards in specific applications such as strength, flexibility, temperature resistance, and chemical durability. Factors such as cost, sustainability, and recyclability also play key roles in material selection. By carefully considering these factors, manufacturers can choose the most appropriate polymer for their products, ensuring they meet the desired performance and safety criteria for the specific industry or application.

Hashtags

#PolymerSelection #MaterialSelection #PolymerApplications #IndustrySpecificPolymers #PolymerInnovation #MaterialScience #PlasticMaterials #CustomPolymers #HighPerformancePolymers #PolymerProperties #IndustryPlastics #TailoredPolymers #PolymerPerformance #PolymerForIndustries #ApplicationBasedPolymers #SustainablePolymers #AdvancedMaterials