The tin container manufacturing industry in India is undergoing a significant transformation, driven by the integration of advanced technologies that streamline production processes, improve efficiency, and enhance product quality. As demand for eco-friendly packaging solutions continues to grow, manufacturers are adopting automation, precision engineering, and smart manufacturing techniques to meet the rising needs of industries like food packaging, beverages, and consumer goods.

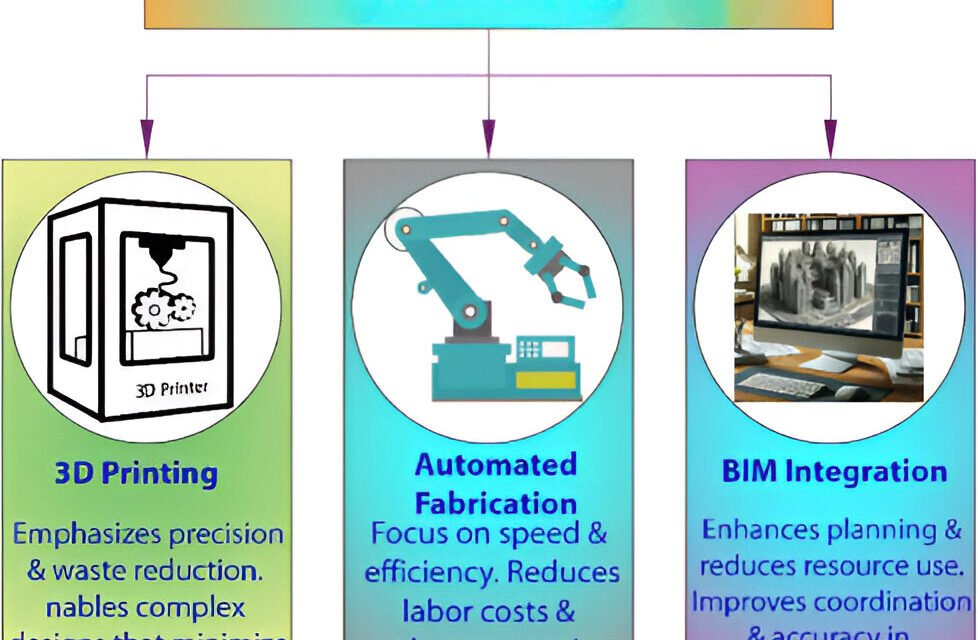

The integration of robotics and computerized control systems has allowed manufacturers to optimize the production lines, reduce human error, and improve consistency in the final product. Additionally, 3D printing and CAD (Computer-Aided Design) technologies are being used to create customized tin container designs, providing flexibility for companies to offer unique packaging solutions that cater to specific consumer preferences. These technological advancements not only enhance the speed and accuracy of the manufacturing process but also contribute to resource efficiency by minimizing material waste and energy consumption.

“The adoption of new technologies has revolutionized tin container production, enabling us to deliver higher quality products at a faster pace, with reduced environmental impact,” said a spokesperson from a leading tin container manufacturer. “By integrating automation and precision tools, we can meet the increasing demand for eco-friendly packaging while ensuring that every product meets stringent quality standards.”Moreover, data analytics is playing a key role in optimizing supply chain management and forecasting production needs, helping manufacturers align output with market demand. As the industry continues to evolve, the technological integration in tin container manufacturing promises to further enhance sustainability, product safety, and efficiency, solidifying the industry’s role as a leader in sustainable packaging solutions.