Tin containers complement plastic and rubber products in hybrid packaging solutions by leveraging the strengths of each material, creating packaging that combines durability, aesthetic appeal, functionality, and cost-effectiveness. These hybrid solutions are increasingly used in industries like food, beverages, cosmetics, and industrial applications, where innovative packaging designs meet consumer and regulatory demands.

1. Advantages of Hybrid Packaging with Tin Containers

A. Enhanced Durability

- Tin’s Role:

- Provides a strong, rigid structure to protect contents from external impacts during transportation and storage.

- Plastic/Rubber’s Role:

- Adds flexibility, shock absorption, or sealing properties to areas requiring adaptability.

- Example:

- A tin coffee can with a plastic resealable lid ensures long-term storage durability while adding convenience for repeated use.

B. Superior Barrier Properties

- Tin’s Role:

- Acts as a complete barrier against light, oxygen, and moisture, protecting perishable or sensitive contents.

- Plastic/Rubber’s Role:

- Enhances sealing capabilities (e.g., gaskets) to ensure airtight and leak-proof packaging.

- Example:

- Metal spice containers with rubberized seals preserve flavor and aroma by keeping moisture out.

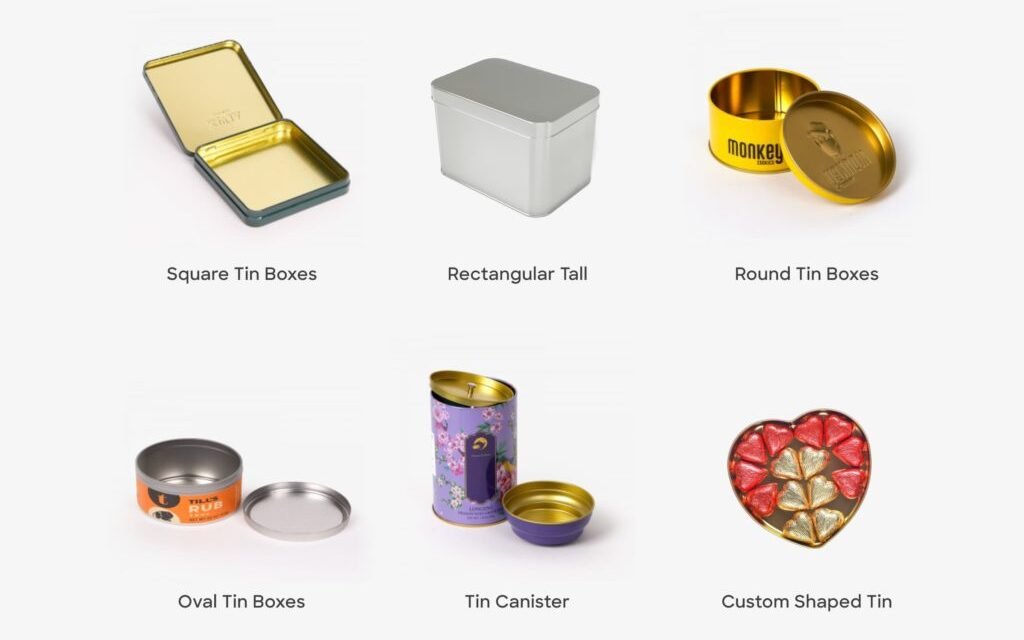

C. Aesthetic and Branding Appeal

- Tin’s Role:

- Offers a premium look with options for embossing, printing, and decorative finishes.

- Plastic/Rubber’s Role:

- Adds versatility in shapes, colors, and textures, enabling unique and consumer-friendly designs.

- Example:

- A luxury gift tin with a clear plastic window combines the upscale appearance of tin with the visibility provided by plastic.

D. Reusability and Convenience

- Tin’s Role:

- Durable structure makes the container reusable, reinforcing eco-friendly branding.

- Plastic/Rubber’s Role:

- Adds features like resealable lids, spouts, or handles for ease of use.

- Example:

- Tea tins with plastic snap-on lids for freshness and reusability.

E. Cost Optimization

- Tin’s Role:

- Provides strength and longevity, reducing the need for excessive materials.

- Plastic/Rubber’s Role:

- Replaces tin in non-structural areas to lower costs while maintaining functionality.

- Example:

- A tin container with a rubberized base for added grip and cost savings compared to a fully metal base.

2. Applications of Hybrid Packaging Solutions

A. Food and Beverage Industry

- Coffee and Tea Tins:

- Tin body for strength and freshness, paired with plastic resealable lids or snap-on rubber seals for convenience.

- Snack Containers:

- Metal containers with plastic windows to allow product visibility while ensuring freshness and durability.

- Beverage Packaging:

- Tin cans with plastic spouts or resealable lids for reusable and eco-friendly drink packaging.

B. Cosmetics and Personal Care

- Cream and Balm Containers:

- Tin exteriors for a premium, aesthetic finish, combined with plastic inserts for lightweight and easy dispensing.

- Lipstick and Solid Perfume Cases:

- Metal shells for strength and style, with rubber or plastic mechanisms for smooth application.

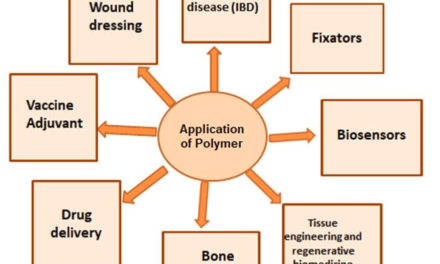

C. Pharmaceutical and Healthcare

- Pill Containers:

- Tin shells for durability and UV protection, paired with child-resistant plastic caps for safety.

- Medical Kits:

- Metal cases with rubber seals to ensure airtight and watertight storage for sensitive medical supplies.

D. Industrial Applications

- Chemical Containers:

- Tin drums for chemical resistance, combined with rubber gaskets for leak-proof seals.

- Paint Cans:

- Tin bodies for strength, with plastic pour spouts or liners for user convenience.

3. Design Features of Hybrid Tin-Plastic/Rubber Packaging

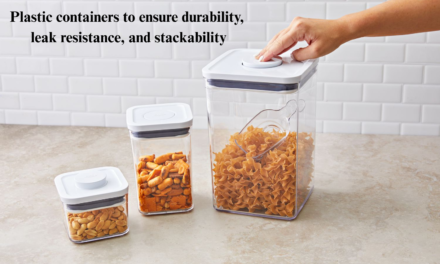

A. Resealable and Reusable Features

- Plastic Lids:

- Used on tin containers for ease of opening, resealing, and extended product use.

- Example: Resealable lids for food tins (e.g., snacks, coffee).

- Rubber Gaskets:

- Ensure an airtight seal in applications requiring long shelf life or protection from moisture.

- Example: Rubber seals on tea or spice tins.

B. Transparent Elements

- Plastic Windows:

- Integrated into tin containers to allow product visibility without compromising durability.

- Example: Specialty cookie tins with clear plastic windows.

C. Ergonomic Additions

- Plastic or Rubber Handles:

- Improve portability and consumer usability, especially for larger containers.

- Example: Paint cans with metal bodies and plastic handles.

- Textured Rubber Bases:

- Add grip to prevent slipping and enhance functionality.

- Example: Rubberized bases on cosmetic tins.

D. Lightweighting

- Plastic Components:

- Replace tin in non-critical areas to reduce overall weight while maintaining structural integrity.

- Example: Tin beverage bottles with lightweight plastic caps.

4. Sustainability Benefits of Hybrid Solutions

A. Recyclability

- Tin Components:

- Fully recyclable, contributing to a circular economy.

- Plastic/Rubber Components:

- Designed for easy separation from tin during recycling, improving waste management.

- Example: Detachable plastic lids on tin containers.

B. Material Efficiency

- Replacing tin with plastic or rubber in specific areas reduces resource use without sacrificing performance.

C. Reuse Potential

- Hybrid containers are often reused by consumers, enhancing sustainability and reducing single-use waste.

5. Challenges and Mitigation in Hybrid Packaging

A. Recycling Complexity

- Challenge:

- Combining tin with plastic or rubber can complicate recycling if the materials are not easily separable.

- Solution:

- Use modular designs with detachable components for simplified recycling.

B. Cost Implications

- Challenge:

- Hybrid packaging may be more expensive than single-material solutions.

- Solution:

- Optimize material use by substituting plastic or rubber only in non-essential areas.

C. Compatibility

- Challenge:

- Ensuring chemical compatibility between tin and plastic/rubber components.

- Solution:

- Use coatings and liners to prevent interactions and ensure product safety.

6. Innovations in Hybrid Packaging with Tin

A. Smart Features

- QR Codes and NFC Tags:

- Embedded in tin bodies, with plastic or rubber components acting as holders for digital engagement features.

- Example: Beverage tins with interactive QR codes linked to promotional content.

B. Biodegradable Components

- Development of biodegradable plastic lids or natural rubber seals to complement recyclable tin bodies.

C. Lightweight Alloys

- Tin containers made from lightweight alloys paired with minimal plastic elements for cost and weight reduction.

Hybrid packaging solutions that combine tin containers with plastic or rubber components offer a balance of durability, aesthetics, functionality, and sustainability, making them ideal for industries like food, cosmetics, and industrial packaging. By leveraging tin’s strength and barrier properties with the versatility of plastic and sealing capabilities of rubber, these solutions cater to consumer demands for convenience, premium design, and eco-friendly options.