The main difference between thermoplastics and thermosetting plastics lies in their molecular structure, manufacturing processes, and end-use applications. Here’s a detailed comparison of both, focusing on how these differences influence their production and applications:

1. Molecular Structure and Behavior Under Heat

- Thermoplastics:

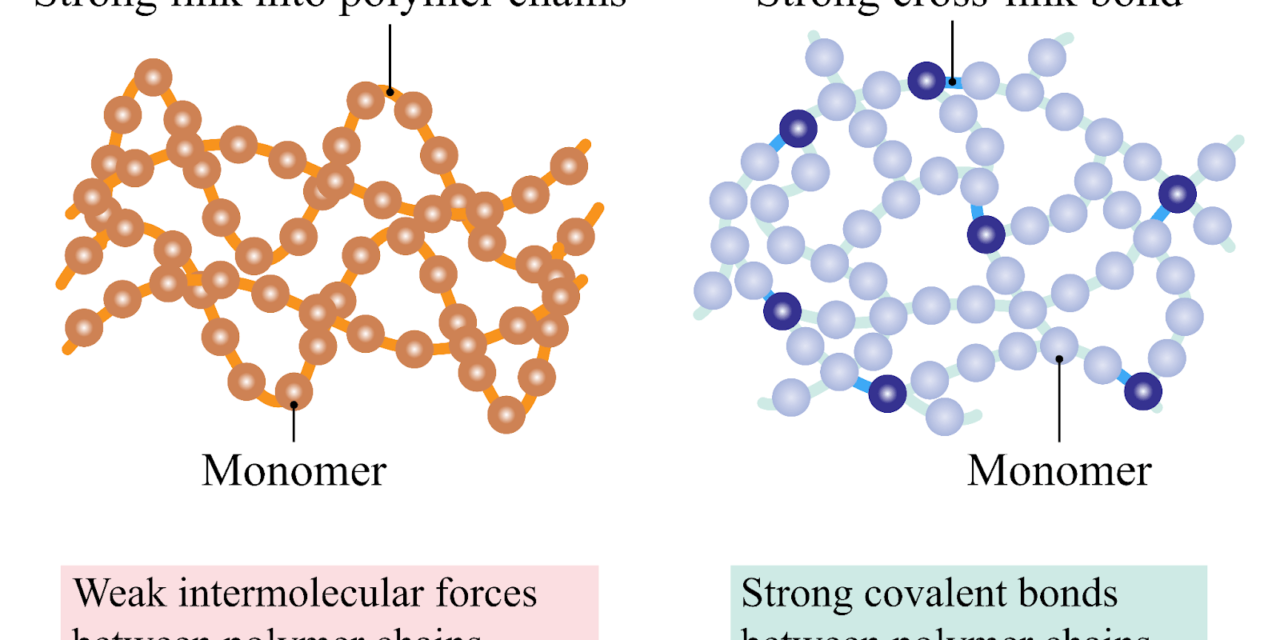

- Molecular Structure: Thermoplastics have a linear or branched molecular structure, meaning the polymer chains are not cross-linked.

- Behavior: When heated, thermoplastics soften and become moldable. Once cooled, they harden again. This process can be repeated multiple times without changing their molecular structure.

- Properties: Thermoplastics are reversible in their response to heat. They are typically more flexible and can be reshaped easily.

- Thermosetting Plastics:

- Molecular Structure: Thermosets have a cross-linked molecular structure. The polymer chains are chemically bonded in a network, forming a rigid structure.

- Behavior: When heated and molded, thermosetting plastics undergo a chemical curing process that sets their shape permanently. Once they are cured, they cannot be remelted or reshaped.

- Properties: Thermosets are rigid, durable, and heat resistant, but they become brittle after curing and cannot be reprocessed.

2. Manufacturing Processes

- Thermoplastics:

- Heating and Shaping: Thermoplastics are heated to their melting point and then shaped using processes like injection molding, extrusion, blow molding, compression molding, and vacuum forming. The plastic can be remelted and reshaped after each cycle.

- Processing Flexibility: Thermoplastics allow for high-volume production with flexibility in design changes and quick turnaround times.

- Ease of Recycling: Since thermoplastics can be repeatedly melted and reshaped, they are easier to recycle than thermosets.

- Thermosetting Plastics:

- Curing and Hardening: Thermosets are typically shaped in their initial state using compression molding, transfer molding, or injection molding, but they are then subjected to heat or chemical agents that trigger a curing reaction, hardening them permanently.

- Irreversible Process: Once thermosetting plastics are cured, they cannot be reheated and reshaped, so the manufacturing process is more rigid and permanent.

- Limited Recycling: Thermosets cannot be easily recycled since they undergo an irreversible chemical change when curing, making them less environmentally friendly in terms of recyclability.

3. Applications

- Thermoplastics:

- Versatility: Thermoplastics are used in a wide range of applications across various industries due to their ability to be easily molded, reshaped, and recycled. They are particularly useful when the product needs to be lightweight, flexible, or cost-effective.

- Common Applications:

- Packaging: Plastic films, bottles, containers.

- Automotive: Interior components, bumpers, dashboard parts.

- Consumer Goods: Toys, household items, furniture.

- Medical: Syringes, blood bags, surgical instruments (especially PVC, polyethylene, and polypropylene).

- Electronics: Casings, insulation materials.

- Key Examples: Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), Acrylonitrile Butadiene Styrene (ABS), Polystyrene (PS), Polycarbonate (PC).

- Thermosetting Plastics:

- Strength and Heat Resistance: Thermosets are ideal for applications requiring high strength, heat resistance, dimensional stability, and electrical insulation. Once set, they provide durable and long-lasting performance in harsh environments.

- Common Applications:

- Automotive: Engine components, brake pads, electrical components.

- Electronics: Insulating materials, circuit boards, potting compounds.

- Construction: Countertops, flooring, adhesives.

- Aerospace: Composite materials for lightweight yet strong structures.

- Key Examples: Epoxy, Phenolic resins, Polyurethane (PU), Melamine, Bakelite.

4. Key Advantages and Disadvantages

- Thermoplastics:

- Advantages:

- Recyclable and can be remelted and reused.

- Easier to process, less costly to produce, and suitable for high-volume manufacturing.

- Flexibility: Can be molded into a wide range of shapes and sizes.

- Durability: While less heat-resistant than thermosets, they offer good durability for many applications.

- Disadvantages:

- Less heat resistance than thermosets, making them unsuitable for high-temperature applications.

- Lower rigidity than thermosets, which might limit their use in certain structural applications.

- Advantages:

- Thermosetting Plastics:

- Advantages:

- Higher heat resistance, making them ideal for high-temperature applications.

- Excellent mechanical properties, strength, and durability, especially for structural and load-bearing components.

- Dimensional stability and electrical insulation properties.

- Disadvantages:

- Cannot be recycled easily, as they cannot be remelted or reshaped after curing.

- Higher production costs and more complex manufacturing processes.

- Brittleness: Once cured, thermosets can become brittle and may fail under certain stress conditions.

- Advantages:

Conclusion

Thermoplastics and thermosetting plastics serve different purposes in the plastics industry, and their manufacturing processes and applications are shaped by their molecular structures and behaviors. Thermoplastics offer advantages in terms of processability, recyclability, and flexibility, making them ideal for high-volume production of items like packaging and automotive parts. In contrast, thermosetting plastics are better suited for applications that demand high strength, heat resistance, and durability, such as in electrical components, automotive engine parts, and aerospace materials. The choice between thermoplastics and thermosets depends on the specific requirements of the product, such as thermal performance, mechanical strength, and recyclability.

Hashtags

#Thermoplastics #ThermosettingPlastics #PlasticTypes #PlasticManufacturing #PlasticApplications #MoldingProcesses #InjectionMolding #CompressionMolding #ThermalProcessing #PlasticProperties #SustainablePlastics #MaterialScience #PlasticForming #HighPerformancePlastics #PlasticProduction #EcoFriendlyPlastics #AdvancedMaterials